Muskel™

Food-grade 100% animal-free nanofibrous scaffolds and microcarriers for scalable cultured meat production.

Making cultured meat production efficient and the meat as tasty as regular meat.

There hasn’t been innovation in how we are growing meat in 10 000 years. Current livestock-based meat production is responsible for:

30%

of Earth’s land

15%

of greenhouse gas emissions

27%

of freshwater

70%

of all antibiotics in the world

Cultured meat is an ideal solution

Cultured meat, also known as cultivated meat, is animal meat (including seafood) that is produced by cultivating animal cells in the bioreactors. This production method eliminates the need to raise animals for food.

99%

lower land use

78-96%

lower greenhouse gas emissions

82-96%

lower water use

0%

antibiotics used

How is cultured meat made?

Cultured meat production process starts with a small sample of animal cells, usually obtained through a biopsy. These cells are then placed in a nutrient-rich growth medium and cultured in a bioreactor, where they multiply. Now, depending on what type of end-product is intended, the cells are seeded on scaffolds that support muscle tissue formation to achieve structured meat (whole cuts, steaks, fillets) or they are harvested and processed into unstructured meat products (sausages, nuggets, or patés).

Gelatex makes high-performance nanofibrous 3D scaffolds and microcarriers for scalable cultured meat mass-production.

Scaffolds

Gelatex’s 3D scaffolds support cell differentiation and muscle tissue formation to achieve a structured steak-like meat that looks, feels and tastes like meat that we are used to.

Microcarriers

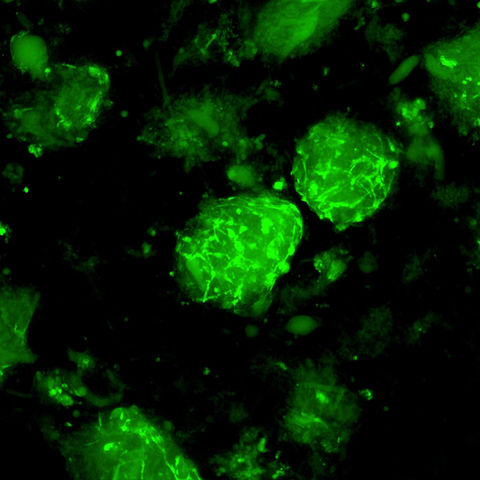

Gelatex’s microcarriers give adherent cells additional surface area in the bioreactors and support their more efficient proliferation and cell density increase.

Benefits of our scaffolds and microcarriers

3D structure that mimics natural ECM

90% lower costs

Works with many cell lines

Stable quality

Automated scalable production

All materials are produced with patented halospinning technology

Halospinning is a high-throughput solution-spinning technology for the production of nano- and microfibers. It works with various synthetic and bio-based raw materials. High-speed production enables cost reduction and unique 3D material morphology creation.

We can adjust the parameters such as the fiber size or porosity, material thickness or density, make the fibers aligned or randomly oriented and optimize the scaffold according to specific requirements.

The 3D structure created by Gelatex’s halospinning technology is the

most similar to the natural ECM

Extracellular matrix

Source: Mdpi.com, Physical Properties of the Extracellular Matrix of Decellularized Porcine Liver, H.Ijima, S. Nakamura, R. Bual, etc. 2018

Gelatex halospun nanofibers

Electrospun nanofibers

Source: Gelatex

Source: Gelatex

Tissue engineering

Promotes cell migration

Unique to our material fibrous structure, during static seeding on Gelatex scaffolds cells exhibit motility and migrate into the scaffold.

3D render of cell distribution inside the scaffold

Image of BHK-21 cells in static culture on a Gelatex scaffold after

24 hours. Cell nuclei are visualized in blue, nanofibers in purple.

Promotes cell proliferation

-

Favorable cell-to-cell and cell-to-scaffold interactions due to halospun fibrous morphology.

-

Incorporation of growth factors, or different ECM proteins and minerals of choice.

-

Material compositions that further facilitate cell attachment.

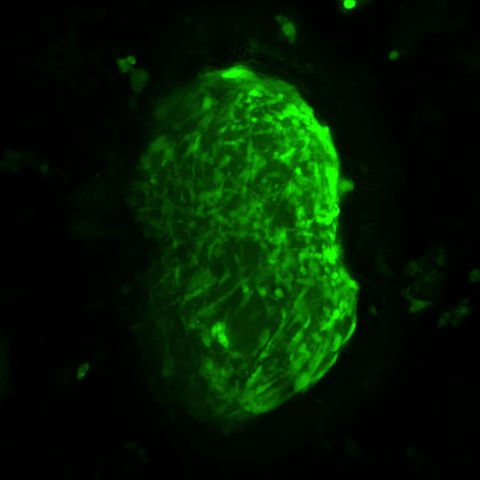

Image of BHK-21 fibroblasts 7 days proliferation on Chitosan scaffolds.

Tissue engineering

Portfolio of products ready to purchase

Scaffolds are available for purchase as a sample kit of 10x10 cm scaffold sheets, as 18x22 sheets, or on rolls.

Microcarriers are available in 3 different formats - microspheres, microgranules and microfibrils.

Currently, we have 7 different compositions for scaffolds and 3 for microcarriers.

Contact us for receiving more detailed product and pricing information.